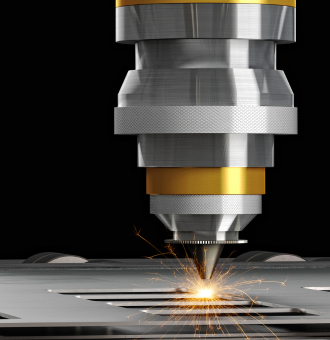

Advanced computer numerical control (CNC) machining services for precise and complex component manufacturing.

The key aspects of precision CNC machining and how it enables the creation of complex components to meet the demands of modern industries.

With a team of skilled engineers and programmers, we can develop customized solutions tailored to your specific design requirements, enabling the successful realization of even the most challenging components and complex projects.

With the utmost commitment to quality, our facility employs advanced inspection equipment and adheres to industry-specific certifications. This ensures that every component leaving our facility meets strict quality benchmarks and regulatory standards.

Beyond providing precision CNC machining services, we offer comprehensive end-to-end support. Our experts collaborates closely from the initial design phase to post-production support, addressing any concerns or modifications along the way.

Computer numerical control (CNC) machining involves the use of computer-aided design (CAD) software to create digital models of the desired components. These digital designs are then translated into specific instructions for CNC machines, which precisely control the movement of cutting tools to shape and form the raw materials. The process eliminates the need for manual intervention, reducing human error and ensuring high accuracy and repeatability.

One of the most significant advantages of precision CNC machining is its ability to work with a wide range of materials, including metals (aluminum, steel, titanium, etc.), plastics, composites, and even exotic materials. This versatility makes CNC machining ideal for various industries, from aerospace and automotive to medical and electronics, where different materials are required to meet specific performance criteria.

Precision CNC machining excels in producing complex components with intricate geometries that would be challenging or even impossible to achieve using conventional machining methods. The technology allows for multi-axis machining, enabling the creation of 3D shapes and contours with exceptional precision. This capability is particularly valuable in industries where miniaturization and intricate designs are becoming increasingly important.

The automated nature of CNC machining ensures consistent results with high accuracy and repeatability. Once the CNC program is established, it can be used repeatedly to produce identical components without compromising quality. This level of consistency is crucial for industries that demand strict adherence to specifications and performance standards.

Precision CNC machining significantly reduces production time and costs compared to traditional machining processes. The automated nature of CNC machines allows for faster material removal rates and minimal setup time between jobs. Additionally, the reduced need for manual labor translates into lower production costs and a quicker time-to-market for products.

To maintain the highest standards of quality, CNC machining incorporates advanced inspection techniques. Computer-aided inspection systems, such as coordinate measuring machines (CMMs), ensure that the produced components meet all required specifications. This stringent quality control process guarantees that the final products meet the exacting demands of the industry.

Copyright © 2025 Core Pretech Pte Ltd. All rights reserved. Website developed by Web Plums.